How Nori is Made | How it Makes Its Way to Our Dining Tables

Introduction

Nori has a crispy texture and melts smoothly in your mouth.

Needless to say, nori seaweed is an indispensable ingredient on the Japanese dining table. It is used as a side dish for rice, as an ingredient in onigiri rice balls, and in a variety of other dishes.

This article explains the process of making nori, so be sure to read until the end.

Preparation ( March to September )

- Cultivation management of filaments (producing seaweed spores): First, we start by producing seaweed seeds. Free filaments and carpospores are planted in oyster or scallop shells to begin cultivation. They grow from spring to summer and produce conchospores. In autumn, the conchospores mature and are released.

- Preparation of fishing grounds (preparation of fields for growing seaweed): There are two types of seaweed farming: pole farming, which is mainly done in inland bays and coastal areas, and floating farming, which is done offshore. For pole farming, preparation is done such as setting up poles, and for floating farming, preparation is done for the farming facilities.

Preparation for sowing and harvesting (September)

The process of attaching the conchospores released from the filaments to a glue net is called seedling collection.

- Offshore seedling collection: This method involves placing seaweed nets and shells with grown filaments at facilities on the sea for seedling collection. This method is becoming less common because it is easily affected by weather and sea conditions. Most seedling collection in the Ariake Sea is done at sea. Once the attachment of conchospores is confirmed, the shells are removed and seedling cultivation begins.

- Land seedling collection: A tank is set up on land, the shells with grown filaments are placed in it, and a seaweed net is wound around a water wheel. This method allows for planned seedling collection while controlling the number of conchospores attached. This method is currently becoming mainstream. After the conchospores have attached, the seaweed net is stored in a refrigerator and stretched out into the sea when sea conditions are favorable.

Seedling raising and production period (October to November)

The nori nets containing the seeds are stretched out in the fishing grounds and seedlings are raised. In order to raise healthy nori seedlings, they are dried out* to prevent the adhesion of other seaweed, to grow disease-free sprouts, and to encourage secondary sprouts to multiply.

*This is the repeated process of using the ebb and flow of the tides to pull seaweed nets out of the seawater and into the air. When done artificially, this is called artificial drying.

After the seedlings have been raised, the nets are divided into those that will be used for cultivation as is (autumn seedling nets) and those that will be frozen for a second crop (frozen nets). They grow to a size that can be harvested in about a month, and from December onwards, the frozen nets are stretched out into the fishing grounds and the production of frozen nets begins.

Harvest ( November to March )

When the nori sprouts grow to 15-20cm, they are harvested. In the past, this was hard work done by hand, but nowadays, the work is done by machine. Boats specially designed for harvesting nori, called diving boats, are used to dive under the nori nets and harvest.

The harvested seaweed goes through the following process at the processing plant, from washing to drying.

Flow at the processing plant

1. Cleaning

The harvested seaweed is washed to remove any sand or dirt adhering to it. It is carefully washed in fresh water to remove any foreign objects.

2. Cutting

The washed nori is cut into small pieces, generally about 2 to 3 mm in size.

3. Drainer

The cut seaweed is drained again using a drainer to remove the moisture. If there is too much moisture, it will not be able to be processed properly in the subsequent steps, so the water is drained until the moisture content is just right.

4. Extraction

The drained seaweed is divided into sheets of seaweed using a machine called a "papermaking machine," which is then placed on a "misu" (a sheet of paper) and pressed into a square shape.

5. Dehydration

The papered nori is then dehydrated further using a sponge-based dehydrator. The sponge presses the raw nori over the already shaped nori, removing the water.

6. Drying

After that, the seaweed is dried in a large nori manufacturing machine (fully automatic nori dryer) by removing moisture and exposing it to hot air. This reduces the moisture content of the seaweed to about 10%.

Drying methods include sun drying, warm air drying, and hot air drying, but in recent years warm air drying and hot air drying have become mainstream. Drying time varies depending on the thickness and moisture content of the seaweed, but it is generally a few hours. It is dried for about 2 to 3 hours while maintaining a temperature of 40 to 80 degrees Celsius.

7. Inspection

After completing these processes, the seaweed is collected by each fishing cooperative and undergoes a quality inspection. The inspection checks color, shape, scent, taste, and the presence or absence of holes or tears. In addition to checking for foreign objects with a metal detector, inspectors visually determine a grade (rank).

8. Bidding

After passing the quality inspection and being graded, the seaweed is put up for auction hosted by the local association, where many trading companies and processing companies participate, selecting the seaweed they need, and purchasing it through competitive bidding.

9. Grilling

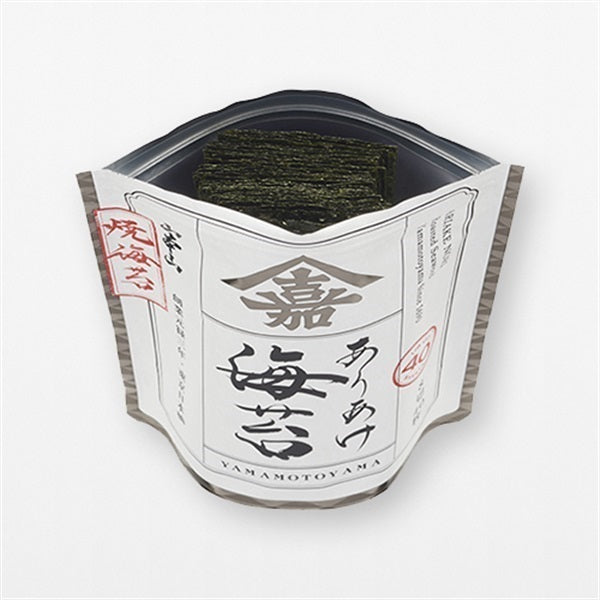

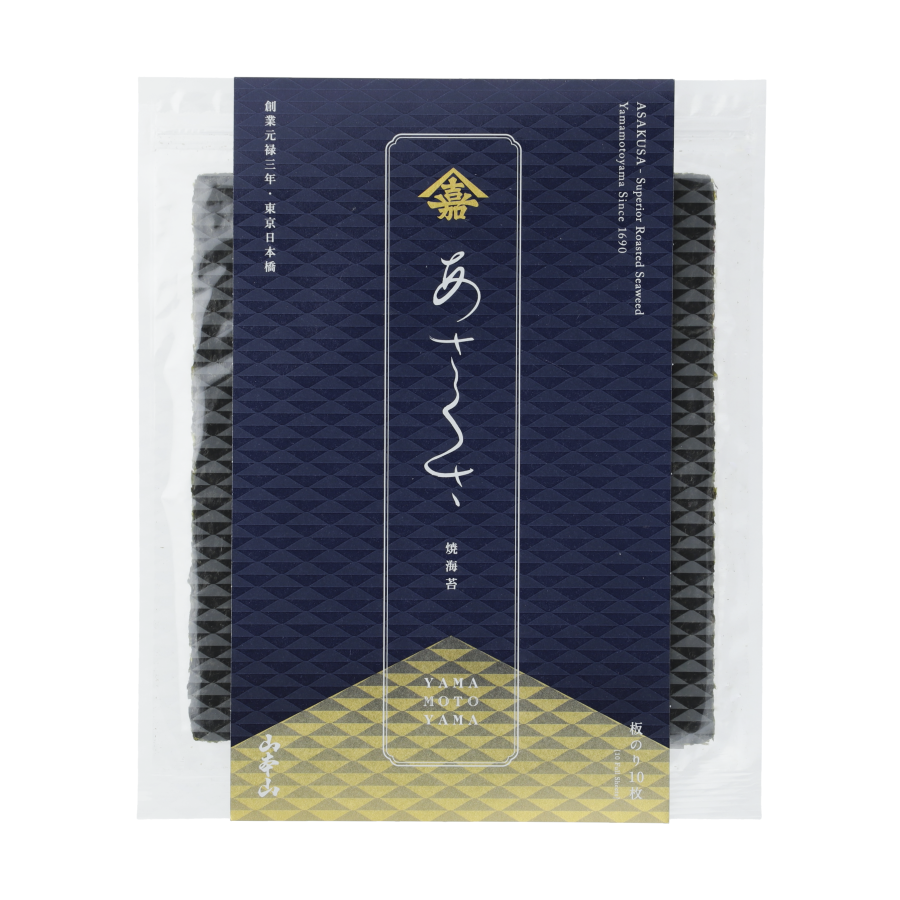

The purchased seaweed is processed by each processing manufacturer, including roasting and seasoning, as well as being cut and packaged. Only seaweed that has passed safety inspections is shipped to supermarkets and retail stores and ends up on our dinner tables.

summary

The above is the entire process from seaweed production to harvesting and processing, but depending on the process, more detailed work may be added.

As you can see, there are many different steps in seaweed processing, and each step affects the flavor and taste of the seaweed. Every step reflects the passion and skills of the seaweed maker.

We eat seaweed without much thought in our daily lives, but we encourage you to try it with the thoughts of the people who make it.